Doing the Research seriesHow Can Multinational Companies Make Their Supply Chains More Sustainable?

1 November 2024, by Newsroom editorial office

Photo: University of Hamburg/Allenbacher/Berg

Companies are urged to take more responsibility for human rights violations and environmental standards in their supply chains. Janine Allenbacher and Prof. Dr. Nicola Berg from the University of Hamburg Business School investigate how companies can make their supply chains more sustainable and prevent human rights violations.

Many customers not only look for reasonable prices but also for quality manufacturing. This holds new challenges for companies. What are you investigating in your project?

Our study focuses on duty of care measures connected to human rights in the corporate world. Simply put: How can multinational companies promote and protect human rights in their own business area and supply chains? Our research was initiated by the ratification of the German Act on Corporate Due Diligence Obligations in Supply Chains (Lieferkettensorgfaltspflichtengesetz, LkSG) by the German Parliament in June 2021.

Large global companies can gear activities along their international value chains to leave a responsible positive or a negative imprint on society and the environment.

On the one hand, their activities across the world create new market space and thus prosperity. On the other hand, global supply chains tend to be complex and opaque at the risk of social and ecological shortcomings, such as human rights violations and environmental pollution. This mostly affects countries with a weak rule of law, or lack thereof.

The mining of so-called conflict minerals, including lithium or cobalt, often comes with major human rights violations while these substances are sorely needed for the transformation building on renewable energies and electric mobility. Child labor, modern slavery, or the destruction of the livelihoods of indigenous peoples are the dark side of sustainability transformation.

What focus do you use in your research?

Under the German Supply Chain Act companies of a certain size are legally obliged to conduct a range of prevention measures with their direct suppliers. However, human rights violations and workplace insecurity are more likely to occur in the lower tiers of supply chains. Due to the complexity and opacity of global supply chains, these suppliers are not explicitly considered in the Act as they can hardly be traced or influenced. This holds new challenges for companies.

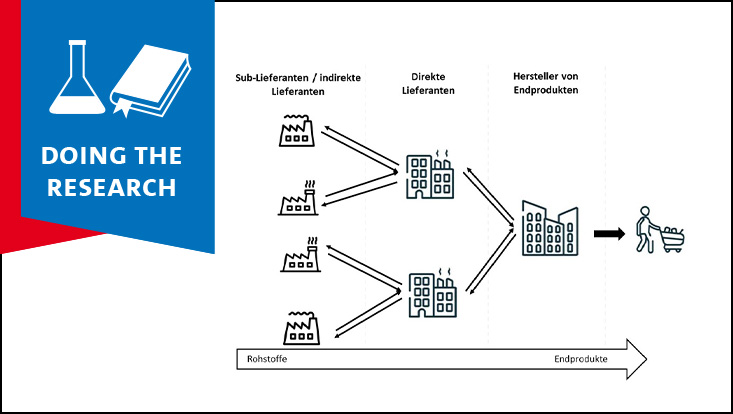

We are therefore mostly interested in the role of direct suppliers of multinational players. They are the central link between sub-suppliers, i.e., manufacturers of preproducts or raw materials, and final product manufacturers. Direct suppliers buy from various sub-suppliers and further process goods before selling them to the company that finishes the product. They can hence set social sustainability standards for lower tiers to help improve sustainability along supply chains significantly. Our study investigates supply chain governance mechanisms.

How can you examine this against the backdrop of complex supply chains?

We used an online questionnaire targeting for hundreds of suppliers of global companies. Our primary focus was on automotive industry suppliers—one of Germany’s major industries. Participating suppliers are thus from the chemical and pharmaceutical sector, mechanical and plant construction, or electrical industries collaborating with subsidiary companies which, in contrast to direct suppliers, are often located outside Germany.

What measures make supply chains sustainable?

One can distinguish between compliance-based and more cooperative approaches. For the former option, companies define appropriate selection criteria and agree contractual assurances, audits, or monitoring before engaging the supplier. Within the cooperative approach, companies offer their suppliers skills acquisition and further training courses as well as joint projects to optimize products or processes.

To what extent did these measures prove effective?

We found that both approaches influenced measures implemented by direct suppliers in a positive way. We gathered empirical evidence that prevention measures in sustainable supply chains create a kind of cascading effect between manufacturers and direct suppliers.

It is remarkable that suppliers’ cooperation-based approaches help them set up their own resources, whereas evaluation-based approaches do not affect this. Even though having one’s own resources is key to motivating suppliers to implement sustainable supply chain approaches for dealing with their sub-suppliers. By focusing on cooperation-based approaches, multinational companies, such as car manufacturers, can support their suppliers in adopting standards in lower supply chain tiers. Based on our results we recommend that human rights officers at least use a mix of both approaches.

Publication

Janine Allenbacher, Nicola Berg: How assessment and cooperation practices influence suppliers’ adoption of sustainable supply chain practices: An inter-organizational learning perspective, Journal of Cleaner Production, Volume 403, 2023, 136852.

Doing the Research

There are approximately 6,200 academics conducting research at 8 faculties at the University of Hamburg. Many students also often apply their newly acquired knowledge to research practice while still completing their studies. The Doing the Research series outlines the broad and diverse range of the research landscape, and provides a more detailed introduction of individual projects. Feel free to send any questions and suggestions to the Newsroom editorial office.